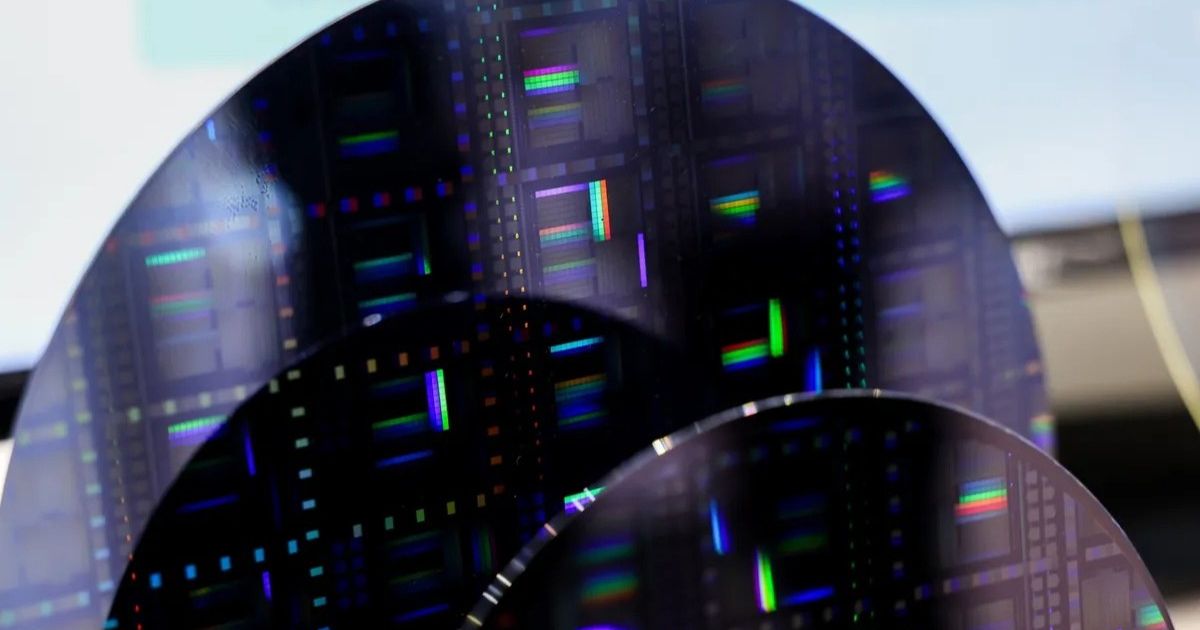

Countries in different parts of the world spend large amounts of taxpayer money to develop or support their semi events industries. This cash flow has led to successes and some failures; The difference between them is usually due to how the money is strategically spent. The Government of India, which has also reduced spending restrictions, should develop a strategy as soon as possible. During the era of Prime Minister Narendra Modi, the federal budgets were very economical in support. But $ 11 billion has already been saved, largely allocated to different projects associated with electronic chips. Last week there was news that another $ 5 to $ 10 billion could follow. These numbers are not small by Indian standards. The government can spend five times on this sector that it spends to support solar panels or cars, and fifty times it plans for dense sectors, such as leather products. According to officials, when the various funds are limited to the sources of the state and the federal government, the government will bear three -quarters of the cost of capital to establish a new facility to manufacture semiconductors. However, India’s goals in semiconductors are not clear whether officials know exactly what they want from their mission in semiconductors, as they seem to have multiple goals, and it always leads to a little chaos when it comes to policy design. Is the purpose of increasing the volume added value in India? Or create jobs? Is the biggest concern of government to limit India’s dependence on China, or to replace imports in general? Do officials believe that local production is needed to support the establishment of a broader electronic sector, or to provide flexibility for the supply chains of the growing car sector? What they say in public talks is involved, because it seems that the focus on the transfer of production is inward, and the promotion of what Moody calls ‘confidence’. This is not a reasonable goal at all. Even the United States cannot really strive for real self -sufficiency self -sufficiency due to the complexity of chips supply chains. There is no one reason that makes us believe that India can do this, especially if we start zero. Dependence on the import of slides. The state should not be too concerned about ‘strategic dependence’ of importing slides, as long as a large percentage of friendly sources such as South Korea, Taiwan or the West. Reducing China’s share in Indian imports can be logical, but semi -conductors are not a sector that should be a concern. Especially because a large percentage of China’s future production of chips will meet local demand. Instead, the focus should be focused on identifying points in the supply chain in which India can quickly enter and expand effectively. Manufacturing has its brilliance, but as many countries around the world have discovered, the starting costs can be unfit. The requirements are also strict. Some companies interested in manufacturing in India may give up this trend because the acquisition of reliable supplies seems very pure water very difficult. The private sector needs more freedom to determine the appropriate positions for its investments. Most of the new factories are aimed at the states controlled by Moody, including the state Gujarat, its hometown. The challenges of employment in India should also focus on addressing these issues first. They also need to work more seriously on an unexpected problem, namely to obtain the right workers. India is perhaps the world’s largest population and claims to have thousands of engineering colleges, but quality control in higher education is very poor to the extent that the new factories can struggle to employ a working force. At least the officials realize that one of the biggest obstacles is the availability of engineers. And if their plans are fruit, their estimates indicate the need of between 10 thousand and 13 thousand trained workers by 2027. Some of the private sector expectations for the lack of talents are much greater. The restructuring of the academies to focus on research and training will be paid off. India should also be aimed at not only working in its factories, but also to meet the requirements of the workforce in the rest of the world. Manufacturing is not the only phase in the supply chain of slides that make a profit. The design, mounting and packaging phases also collect about half of the sector revenue. It already comes from India five chips in the world, but there are only 7% of the actual design facilities. New meeting factories also appear and the support of the government is increasing. But it is possible to do more than New -Delhi his money is more aware of. The actual profit will come through investment in these parts of the supply chain in which India has a relative superiority. Finally, the factories can then come as soon as an operating ecosystem develops. There is no sense in obsession with confidence, when a giant country like the United States is just an equipment of a global machine.

India has dreams in semiconductors but it doesn’t have a strategy